Mikhail Naganov

AES Conference on Headphones, Part 2—ANC, MEMS, Manufacturing

I continue to share my notes from the recent AES Conference on Headphones. This post is about Active Noise Cancellation (ANC), Microelectromechanical (MEMS) technologies for speakers and microphones, and topics on headphones manufacturing, measurement, and modelling.

Active Noise Cancelling

Apparently, Active Noise Cancelling (ANC) is a big thing for the consumer market and is an interesting topic for research because it involves both acoustics and DSP. ANC technologies save our ears because they allow listening to music in noisy environments without blasting it at levels that damage hearing. Typically, ANC is implemented on closed headphones or earphones as their physical construction allows to attenuate some of the noise passively, especially at middle and high frequencies. Low frequency noise has to be eliminated using active technologies. Since this requires embedding electronics into headphones, even for wired models, it also gives headphone designers a good opportunity to add “sound enhancing” features like active equalization and crossfeed.

The obvious approach to active noise cancellation is to put a microphone on the outer side of the ear cup and generate an inverse sound via the speaker to cancel the noise at the eardrum. However, as there is always some leakage of the noise inside the ear, “slow” or too aggressive noise inversion will create unpleasant comb filter effect due to summing of the noise with its delayed inverted copy.

An interesting idea that helps to win some time for more precise noise cancelling is to capture the noise from the ear cup on the opposite ear, as in this case the acoustic wave of the noise will have to travel some extra distance over the head. However, as an engineer from Bose has explained to me, the actual results will depend on the plane of the sound wave with respect to the listener.

One consideration that has to be taken into account when generating an inverse noise is to avoid creating high peaks in the inverse transfer function from notches in the original function. The process that helps to avoid that is called “regularization”. It is described in this AES paper from 2016.

Use of ANC puts additional requirements on the drivers used in the headphones. As low frequency noise needs the most attenuation, a high displacement speaker driver is required to produce an adequate counter pressure. This typically requires increasing the size of the driver which in turn increases the amount of distortion at higher frequencies. This paper contains an interesting analysis of these effects for two commercial drivers.

“Hear Through”

“Hear Through” is a commonly used term for describing the technology that presents the environmental sounds to the listener wearing noise cancelling headphones. This is achieved by playing the sound captured by the outer microphone into the corresponding ear (basically, performing a real-time “dummy head” sound field capture which I was describing in the previous post). The Sennheiser AMBEO headset and AKG N700NC headphones implement “hear through”, however not perfectly according to my experience—the external sound has some coloration and some localization problems. Although, that doesn’t affect the ability to understand speech, it still feels unnatural, and there is some ongoing research to make “hear through” more transparent.

According to the study described in the paper “Study on Differences between Individualized and Non-Individualized Hear-Through Equalization…”, there are two factors that affect “transparency” of the played back sound. First, it is the fact that closed headphones act as a filter when interacting with the ear, and this filter has to be compensated. Second, it’s already mentioned sound leakage. Because “hear through” involves sound capture, processing, and playing back, it has non-negligible latency that creates a comb filter with the original leaked noise. The researchers demonstrated that use of personal “hear through” equalization (HT EQ, specific both to the person and the headphones) can achieve very convincing reproduction. However, the acquisition of HT EQ parameters has to be performed in an anechoic room (similar to classic HRTF acquisition), and thus is not yet feasible for commercial products.

MEMS Technologies

I must admit, I’ve been completely unaware of this acronym before I attended the conference. But turns out, this technology isn’t something new. A portable computer you use to read this article contains several MEMS microphones in it. The key point about this technology is that resulting devices are miniature and can be produced using the same technologies as the ones used for integrated circuits (IC). The resulting device is packaged into a surface mounted (SMD) component. The use of IC process means huge production volumes are easily possible, and the variation in components is quite low.

Initially I thought that MEMS means piezoelectric technology, but in fact any existing transducer technology can be used for engineering MEMS speakers and microphones: electret, piezo, and even electrostatic as was demonstrated in the paper “Acoustic Validation of Electrostatic All-Silicon MEMS-Speakers”.

MEMS microphones are ubiquitous. The biggest manufacturer is Knowles. For example, their popular model SPH1642HT5H-1 has high SNR and low THD costs less than $1 if bought in batches. Due to the miniature size MEMS microphones are omnidirectional across the whole audio range. Because of this fact I was wondering whether MEMS microphones can be used for acoustic measurements. Turns out, researchers were experimenting with them for this purpose since 2003 (see this IEEE paper). However, the only commercially available MEMS measurement microphone I could find—from IK Multimedia—doesn’t seem to provide a stellar performance.

Engineering a MEMS speaker is more challenging than a microphone due to miniature size. Apparently, the output sound level decays very quickly, so currently they can’t be used for laptop or phone speakers. The only practical application for MEMS speakers at the moment is in-ear headphones where the effect of a pressure chamber in an occluded ear canal boosts their level a bit. A prototype of MEMS earphones was presented in the paper “Design and Electroacoustic Analysis of a Piezoelectric MEMS In-Ear Headphone”. The earphone is very minimalist and can be made DIY because it basically consists of a small PCB with a soldered on MEMS speaker and a 3D-printed enclosure. The performance isn’t satisfying yet, but there is definitely some potential.

Headphones Manufacturing, Measurement, and Modelling

This is a collection of notes that I’ve gathered from the workshop on “Practical Considerations of Commercially Viable Headphones” (a “workshop” format means that there was no paper submitted to AES), my chats with engineers from headphone companies, and conversations with the representatives of measurement equipment companies.

Speaker driver materials

The triangle of driver diaphragm properties:

The effect of the low mass is in a better sensitivity, as lower force is required to move the diaphragm. Good mechanical damping is needed for producing transients truthfully and without post-ringing. And the higher the rigidity, the more the diaphragm resembles a theoretical “piston”, and thus has lower distortion.

In practice, it is hard to satisfy all of the properties. For example, the classical paper cone diaphragm has good rigidity but high mass. Rigid metal diaphragms may lack damping and “ring”. I would also add the fourth dimension here—the price. There are some diaphragms on the market that satisfy all three properties, but they are very expensive due to use of precise materials and a complicated manufacturing process.

Driver diaphragms for headphone speakers are typically produced from various polymers as they can be stamped easily. In terms of the resulting diaphragm quality, the following arrangement has been presented, from worst to best:

- PET (Polyethylene terephthalate);

- PEN (Polyethylene naphthalate);

- PEI (Polyetherimide);

- PEEK (Polyether ether ketone).

However, it looks like even better results are achieved with beryllium foil (used by Focal company), but these diaphragms are quite expensive.

If we step away from dynamic drivers, planar magnetic drivers are very well damped and have a lightweight diaphragm, they also move as a plane. The problem with their production is a high chance of defect, each speaker has to be checked individually, that’s why they mostly used in expensive hi-end headphones. Big companies like AKG, Beyerdynamic, Sennheiser, and Shure use classic dynamic drivers even on their flagship models.

Measurements and Tuning

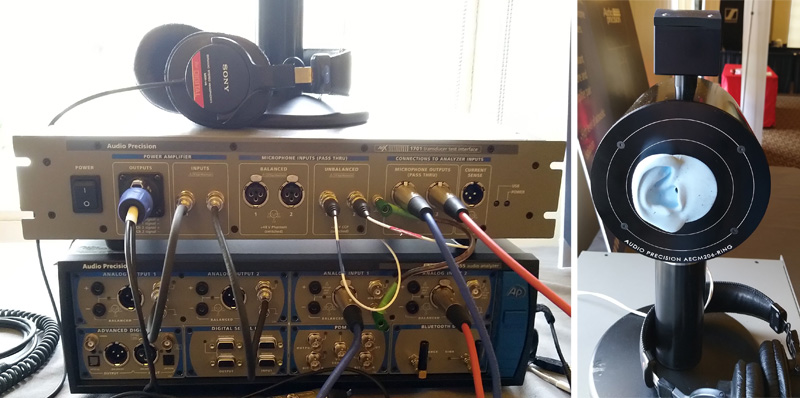

Regarding the equipment, here is a measurement rig for over-ear and in-ear headphones from Audio Precision. It consists of APx555 Audio Analyzer, APx1701 Test Interface (basically a high-quality wide bandwidth amplifier), and AECM206 Test Fixture to put the headphones on.

APx555 is modular. The one in the picture is equipped with a Bluetooth module, and I’ve been told that it supports HD Audio protocols: AAC, aptX, and LDAC.

Besides AP’s AECM206 test fixture, a full head and torso simulator (HATS), e.g. KEMAR from GRAS can be used. For earphone measurements it is sufficient to use an ear simulator as earphones do not interact with the pinna.

Companies Brüel & Kjær and Listen Inc also presented their measurement rigs and software. Prices on this equipment are on the order of tens of thousands of dollars, which is what you would expect.

Measuring the headphones correctly is a challenging problem. There is a nice summary in these slides, courtesy of CJS Labs. The resulting frequency response curves can vary due to variations in placement of the headphones on the fixture. Usually, multiple trials are required with re-positioning of the headphones and averaging.

When measuring distortion, the first requirement is to perform it in quiet conditions to avoid external noise from affecting the results. Second, since measurement microphones are typically band-limited to the audio frequencies range, THD measurement at high frequencies can’t be done adequately using the single tone method. Instead, non-linearity is measured using two tone method (intermodular distortion).

The usual “theoretical” target for headphones is to imitate the sound of good (linear) stereo loudspeakers. The deviation between frequency response of the headphones from the frequency response recorded from loudspeakers using a HATS simulator is called “insertion gain”. Ideally, it should be flat. However, listening to the speakers can happen under different conditions: extremes are free field and diffuse field. So the real insertion gain of headphones is never flat, and it is usually tweaked according to the taste of the headphones designer.

There is one interesting effect which occurs when using closed-back headphones or earphones. Due to ear canal occlusion, the sound level from headphones must be approximately 6 dB higher to create the same perceived loudness as from a loudspeaker. This is called “Missing 6 dB Effect”, and a full description can be found in this paper. Interestingly, the use of ANC could help with reducing the effects of occlusion, see the paper “The Effect of Active Noise Cancellation on the Acoustic Impedance of Headphones” which was presented on the conference.

Speaking of ANC, measuring its performance is yet another challenge due to the absence of industry-wide standards. This is explained in the paper “Objective Measurements of Headphone Active Noise Cancelation Performance”.

Modelling and Research

Thanks to one of the attendants of the conference, I’ve learned about works of Carl Poldy (he used to work at AKG Acoustics, then at Philips), for example his AES seminar from 2006 on Headphone Fundamentals. It provides classical modelling approaches using electrical circuits and two-port ABCD model. The two-port model can be used for simulating in the frequency domain. Time domain simulation can be done using SPICE, see this publication by Mark Kahrs.

However, these modelling are more of “academic” nature. “Practical” modelling was presented by the representatives of COMSOL company. Their Multiphysics software can simulate creation of acoustic waves inside the headphones and how they travel through the ear’s acoustic canals and bones. This was quite impressive.

Another interesting paper related to research, “A one-size-fits-all earpiece with multiple microphones and drivers for hearing device research” presents a device that can be used in hearables research. It consists of an ear capsule with two dynamic drivers and two microphones. It is called “Transparent earpiece”, more details are available here.